Search

START TYPING AND PRESS ENTER TO SEARCH

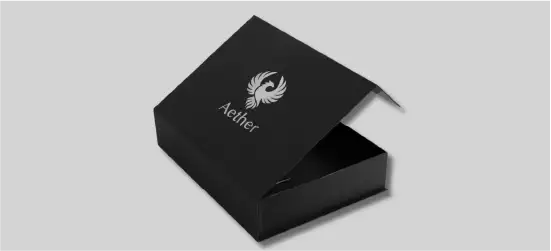

Honor the quality of your creation with packaging that matches it. We partner with you to craft truly unforgettable unboxings using premium materials and complete customization, because the first touch should feel as high-end as the product inside.

Check your desired box style or find the similar product boxes to your product nature from given categories

Thriving in today’s market requires premium packaging. As your ultimate rigid box partner, PackagingShelter brings your boldest designs to life with stunning clarity on any size, shape, or material. Add a tangible layer of luxury with our embossing, debossing, and foil imprinting services. This final touch ensures your rigid boxes communicate quality and attention to detail directly to your customers. Discovering your perfect packaging is easy. Browse our user-friendly store categorized by Industry, Shape, Material, and Style. We provide free shipping to the USA, Canada, UK, Australia, and Germany—no hidden fees, ever.

Add a touch of elegance with foiling, embossing, and other decorations that make your boxes stand out.

It is a smooth, non-reflective plastic film that gives a subdued, elegant appearance.

It is also a plastic film that delivers a shiny, reflective finish that can make colors appear more vibrant and images more striking.

Varnish is a clear, transparent coating that is applied to protect the printing material against fingerprints, smudges and scuffs, and to enhance the depth of the packaging colors and overall appearance of the boxes.

This method of printing produces decorative and shiny effects by using metallic foils or pigmented foils on a surface.

In addition to the raised surface design, it adds the effect of a three-dimensional and tactile experience to the product.

Basically, it is the process of pressing a design into a surface, thereby creating an effect that is depressed or indented.

UV varnishes are clear varnishes that use ultraviolet light to enhance the appearance of your products.

A window cut-out in boxes allows visibility of the product inside while maintaining packaging integrity.

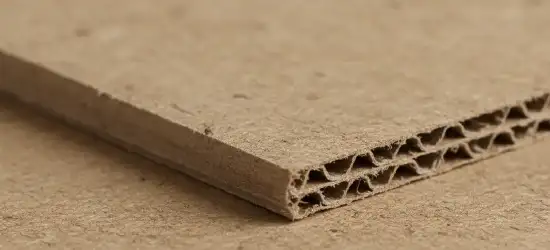

It is extremely thick and rigid, ideal for packaging heavy or fragile items or luxury products.

It is the ultra-thick and most durable material, ideal for packaging extra-heavy or delicate luxury items.

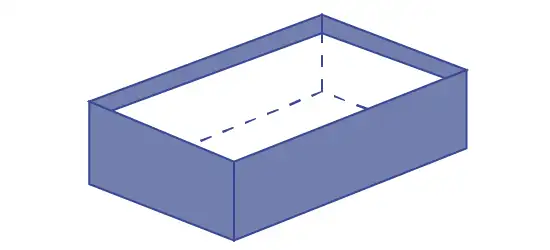

A rigid box is a premium packaging solution defined by its sturdy, non-collapsible structure. Unlike folding cartons, which ship flat and are assembled by the end user, rigid boxes are manufactured pre-formed and maintain their shape at all times. This inherent construction conveys an immediate sense of luxury, quality, and value. Consequently, they are the preferred choice for high-end electronics like smartphones, watches, and headphones; luxury goods such as jewelry, perfumes, and spirits; cosmetics and skincare products; gift and presentation boxes; and special edition products like games and collectibles.

Our Custom Rigid Boxes are meticulously crafted to provide a premium, luxurious appearance while ensuring robust protection for products like cosmetics, jewelry, electronics, or gift sets. These non-foldable, high-end boxes are built using eco-friendly materials and a precise construction process that guarantees durability and style. Here are a few major steps while making rigid boxes.

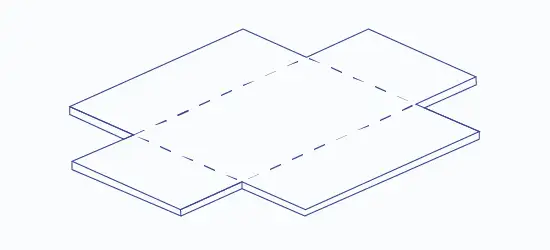

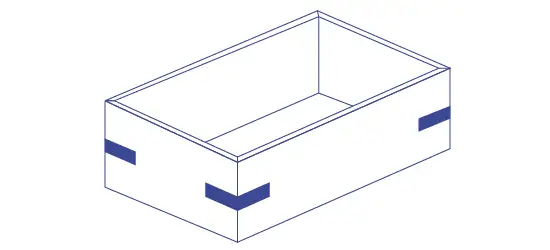

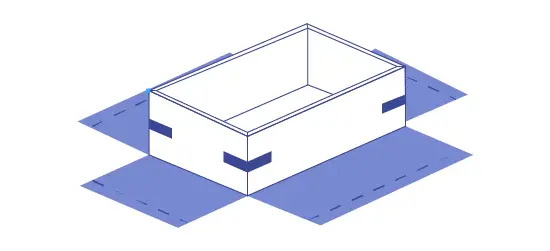

The construction of our rigid boxes, also known as set-up boxes, starts with creating a solid foundation using greyboard, a thick chipboard made from recycled fibers. This greyboard is precisely cut to exact dimensions for the base, sides, and lid (if included), forming a non-collapsible frame typically 1.5 to 3mm thick. With a breaking strength of up to 50-60 pounds, this core ensures robust protection for heavy or fragile items like glassware or electronics. You can choose standard greyboard for a cost-effective, raw look or opt for white or black greyboard for a sleek, polished interior perfect for luxury packaging.

Once cut, the greyboard pieces are carefully glued together to form a seamless, rigid structure. This assembly process creates a sturdy, non-foldable box that holds its shape without collapsing, unlike standard folding cartons. The glued framework, whether for a simple box or one with a lid, is designed to maintain its integrity, providing a reliable foundation that safeguards products during shipping or display while offering a premium, professional appearance.

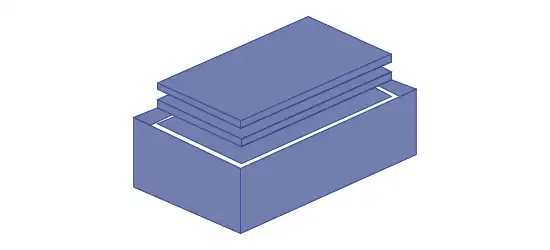

A decorative outer wrap, acting as the box’s “skin,” is added to enhance style and brand appeal. This wrap can be made from glossy white cardboard (Solid Bleached Sulfate) for vibrant printing, uncoated stock for a minimalist vibe, textured stock for a tactile feel, or metalized cardstock in silver, gold, or holographic finishes for a glamorous effect. Brown kraft offers a rustic, eco-friendly aesthetic, while CCNB or CCKB provides vibrant prints with sturdy support, and specialty papers like soft-touch or embossed options deliver unique textures. The wrap is precision-cut, adhered to the greyboard core, and meticulously folded to ensure a smooth, professional finish, using 100% recyclable materials sourced from Sustainable Forestry Initiative-certified suppliers.

To enhance functionality and create a memorable unboxing experience, custom inserts or padding can be incorporated. Options include cardstock or corrugated dividers, soft foam, EVA foam, silk or velvet lining, cotton pillows, or silk pouches, all tailored to fit the box’s interior dimensions. These inserts are either glued or securely placed inside, ensuring products like jewelry or electronics stay safe while adding a luxurious touch that elevates the presentation for gifts or high-end retail.

Every rigid box is crafted from 100% recyclable, biodegradable materials, making them as planet-friendly as they are stunning. By sourcing greyboard and wraps from Sustainable Forestry Initiative-certified suppliers, we ensure the construction process minimizes environmental impact while delivering premium quality. This commitment to sustainability makes our rigid boxes a smart choice for eco-conscious brands without compromising on strength or style.

The construction of our rigid boxes, also known as set-up boxes, starts with creating a solid foundation using greyboard, a thick chipboard made from recycled fibers. This greyboard is precisely cut to exact dimensions for the base, sides, and lid (if included), forming a non-collapsible frame typically 1.5 to 3mm thick. With a breaking strength of up to 50-60 pounds, this core ensures robust protection for heavy or fragile items like glassware or electronics. You can choose standard greyboard for a cost-effective, raw look or opt for white or black greyboard for a sleek, polished interior perfect for luxury packaging.

Once cut, the greyboard pieces are carefully glued together to form a seamless, rigid structure. This assembly process creates a sturdy, non-foldable box that holds its shape without collapsing, unlike standard folding cartons. The glued framework, whether for a simple box or one with a lid, is designed to maintain its integrity, providing a reliable foundation that safeguards products during shipping or display while offering a premium, professional appearance.

A decorative outer wrap, acting as the box’s “skin,” is added to enhance style and brand appeal. This wrap can be made from glossy white cardboard (Solid Bleached Sulfate) for vibrant printing, uncoated stock for a minimalist vibe, textured stock for a tactile feel, or metalized cardstock in silver, gold, or holographic finishes for a glamorous effect. Brown kraft offers a rustic, eco-friendly aesthetic, while CCNB or CCKB provides vibrant prints with sturdy support, and specialty papers like soft-touch or embossed options deliver unique textures. The wrap is precision-cut, adhered to the greyboard core, and meticulously folded to ensure a smooth, professional finish, using 100% recyclable materials sourced from Sustainable Forestry Initiative-certified suppliers.

To enhance functionality and create a memorable unboxing experience, custom inserts or padding can be incorporated. Options include cardstock or corrugated dividers, soft foam, EVA foam, silk or velvet lining, cotton pillows, or silk pouches, all tailored to fit the box’s interior dimensions. These inserts are either glued or securely placed inside, ensuring products like jewelry or electronics stay safe while adding a luxurious touch that elevates the presentation for gifts or high-end retail.

Every rigid box is crafted from 100% recyclable, biodegradable materials, making them as planet-friendly as they are stunning. By sourcing greyboard and wraps from Sustainable Forestry Initiative-certified suppliers, we ensure the construction process minimizes environmental impact while delivering premium quality. This commitment to sustainability makes our rigid boxes a smart choice for eco-conscious brands without compromising on strength or style.

Our printing options ensure your rigid boxes pop with vibrant, high-quality designs that capture attention. Below are the printing techniques and finishes we offer to bring your logos, designs, and colors to life.

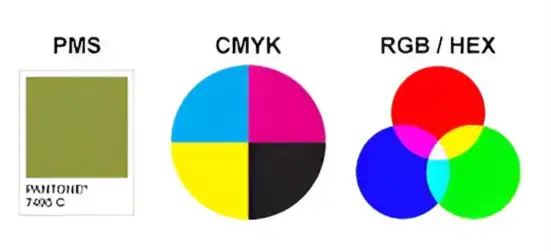

Offset or litho printing transfers CMYK colors (cyan, magenta, yellow, black) from a metal plate to a rubber blanket, then onto the box’s surface, creating crisp, professional results. It’s ideal for large runs, detailed graphics, or bold logos on luxury packaging, delivering sharp details and consistent colors that make your brand shine on cosmetics, gift sets, or electronics.

Digital printing uses CMYK inks to produce high-resolution prints, perfect for smaller batches or intricate artwork. It’s cost-effective with no plate fees, making it a great choice for startups or quick-turnaround orders, offering flexibility to bring your custom designs to life with vibrant clarity.

UV printing applies UV-cured inks for bold, durable colors that resist fading. Available as spot UV for glossy highlights on specific areas or flood UV for full glossy coverage, it adds a premium, long-lasting shine to your boxes, creating a striking visual effect that stands out on retail shelves.

Silk screen printing uses mesh screens and stencils to apply solid, bold colors, ideal for textured surfaces like metallic or kraft paper. It’s perfect for simple logos or bold text, offering durability and versatility to make your design pop on unique or specialty wraps.

Choose CMYK for vibrant, multi-colored designs, PMS (Pantone Matching System) for precise brand color matching to ensure your logo’s exact shade, or custom metallic and neon inks for a unique, standout look that grabs attention and elevates your brand’s presence.

Manufacturing Custom Rigid Boxes is easy for us! You can get your boxes delivered to your doorstep in just four simple steps.

WhatsApp us